Hand woodworking tools are the foundation of any woodworking shop. From saws and planes to chisels and hammers, hand tools allow you to work and shape wood with precision and care. Learning about the different types of hand tools, when to use them, and how to keep them in top working condition is key for both beginner and experienced woodworkers alike. This guide will provide an overview of the most common and useful hand woodworking tools to add to your repertoire.

Key Takeaways

| Takeaway |

|---|

| Table saws, miter saws, circular saws, routers, sanders, and drills are versatile, foundational power tools. |

| Jigsaws, bandsaws, scrollsaws, and lathes allow for more intricate and curved cuts. |

| Consider your skills, interests, workspace, and budget when choosing tools. Quality tools are worth the investment. |

| Follow all manufacturer safety instructions to prevent serious injuries from blades and kickback. |

| Use push sticks, featherboards, and other aids to keep hands safely away from cutting. |

| Develop your skills with basic tools before advancing to more complex power machinery. |

| With practice and caution, power tools can help take your woodworking to a higher level. |

| Hand woodworking tools like planes, chisels, and handsaws, give more control, finesse, and precision than power tools. |

| Choose high-quality tools that will last, starting with basic tools that match your skill level and budget. |

| Learn to use tools as intended, keep them sharp, don’t force them, and work safely. |

| Start with simple beginner projects to develop skills before moving onto complex builds. |

| Mastering hand tools is deeply rewarding and connects you with woodworking tradition. |

What Are Hand Woodworking Tools?

Hand woodworking tools are tools that are operated and controlled directly by the woodworker’s hands, rather than through automation or electricity. They range from handheld tools like saws, chisels, and planes to workbench tools like vises, clamps, and work supports.

Hand tools give the woodworker more control and finesse when cutting, shaping, and joining wood. While power tools can make the work go faster, hand tools allow for tighter tolerances, more precision, and a smoother finish. Many woodworkers find that they prefer to do the beginning and end stages of a project with hand tools, reserving power tools for the intermediate rough work.

Benefits of Using Hand Woodworking Tools

There are many advantages to using hand woodworking tools:

- More control and finesse – The direct feedback from hand tools allows superior control over the cut or motion. This leads to accuracy and precision.

- Quieter and calmer workspace – No loud motor noises. Just the sound of tools on wood.

- Tradition and craftsmanship – Hand tool woodworking carries on the tradition of old world craftsmanship. It connects you with past masters.

- Space and cost savings – You don’t need a lot of machinery taking up room in your shop. Hand tools are relatively inexpensive.

- Safer – No spinning blades or other hazards associated with power tools. Hand tools allow you to work at your own pace safely.

- Slower and more methodical – Working with hand tools forces you to slow down and think through each step. This results in fewer mistakes.

- Satisfaction – Mastering hand tools to create furniture and projects is deeply rewarding. You feel more connected to the craft.

Whether you are a beginner looking to learn the basics or a master craftsman keeping traditions alive, hand woodworking tools have stood the test of time for good reason.

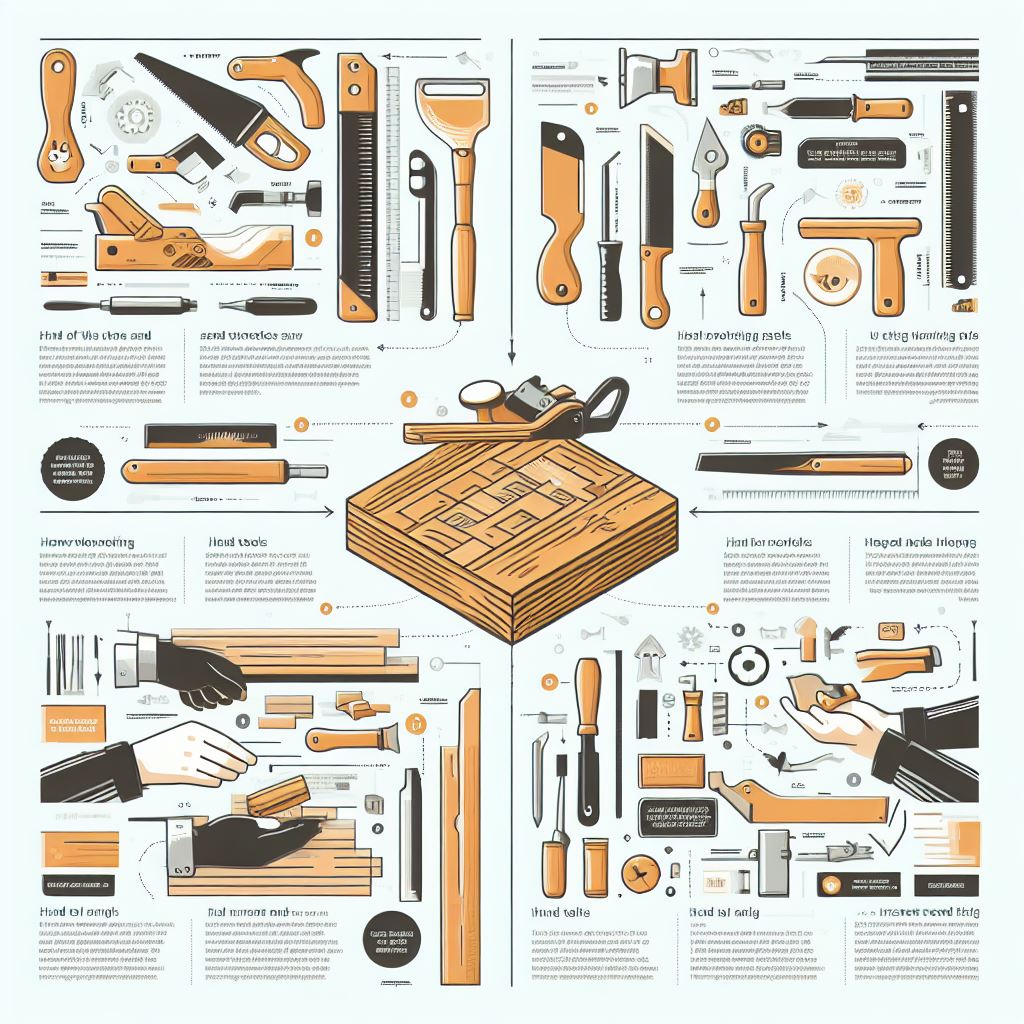

Common Types of Hand Woodworking Tools

There are many types of hand woodworking tools available to tackle different aspects of the woodworking process. Here are some of the most common and useful:

Saws

Saws are used to precisely cut wood grain. There are several types for different purposes:

- Handsaws – All-purpose wood saws for ripping, crosscutting, mitering. Come in rip or crosscut teeth.

- Backsaws – Saw held in a frame with stiff backing. Good for fine joinery and miter cuts.

- Coping saws – Small saw for cutting curves and interior cutouts. The thin blade can pivot.

- Fret saws – Similar to coping saw but with a larger frame and deeper throat for ornamental and relief cuts.

Planes

Planes shave and smooth wood surfaces:

- Jack planes – All-purpose bench planes in the 12-14 inch range. Good for flattening, squaring, and dimensioning.

- Smooth planes – With finely set blades, these produce final smooth surfaces at the end stage. Typically 9 inches long.

- Block planes – Small, one-handed planes under 9 inches long. Great for end grain, chamfers, and small surfaces.

- Shoulder planes – Designed to plane the shoulders of tenons for precise fitting of joints.

- Rabbet planes – Remove material from the edges of boards to create rabbets and steps.

Chisels

Chisels cut, shape, and pare wood:

- Bench chisels – All-purpose bevel-edged chisels secured in a mallet or by hand. Ranges from 1/4 to 2 inches wide.

- Mortise chisels – Sturdier, thicker versions of bench chisels meant for chopping mortises.

- Paring chisels – Long, thin blades for controlled paring and fine shaping.

- Carving chisels – Made for specialized hand carving work with many different profiles.

Hammers

Hammers drive and assemble:

- Claw hammers – Standard carpenter’s hammer with claw on one end to remove nails.

- Mallets – Wooden hammers to strike chisels. Softer than metal to avoid damage.

- Ball peen hammers – One end rounded into a ball peen to shape metal.

Other Essential Tools

- Squares – Combination squares, drafting squares, try squares. All ensure perfect 90 degree angles.

- Bevel gauges – Adjustable tools to measure and transfer precise angles.

- Marking gauges – Mark parallel lines at set distances from an edge.

- Spokeshaves – Shaves smooth, flowing convex and concave curves.

- Rasps and files – Coarse and fine teeth for aggressively or gently shaping wood.

- Clamps – Essential workholding tools to secure pieces as glue dries.

- Workbench – Sturdy table that holds workpieces while tools are used on them.

How to Choose Hand Woodworking Tools

With so many options available, it can be daunting to decide which hand woodworking tools to purchase first when starting out. Follow this criteria when making your selections:

Consider Your Skill Level

As a beginner, opt for basic tools like a jack plane, smoothing plane, combination square, and a small selection of saws and chisels. Add other specialty tools later as your skills progress.

Consider Your Needs

Think about the types of projects you will make and let this guide your purchases. For fine furniture, a dovetail saw and rabbet plane are essential. For general carpentry, a crosscut saw and claw hammer are more useful.

Consider Your Budget

Quality hand tools are an investment that will pay off over years of use. But you don’t need to buy everything at once. Start with a few professional grade tools and gradually build your collection.

Buy Quality That Will Last

Stainless steel blades, strong handles, precision machining – don’t compromise on tool quality. Top brands like Lie-Nielsen, Veritas, and Ashley Iles live up to their price tags.

Buying the right hand woodworking tools may take some research and planning. But assembled thoughtfully, your set of tools will serve you loyally for many satisfying years in the shop.

Using Hand Woodworking Tools Safely and Effectively

Once you have assembled a collection of hand woodworking tools, it’s important to learn how to use them safely and get the best results from them. Here are some tips:

Always Wear Safety Glasses

Protect your eyes from flying chips and debris. It only takes one slip for life-changing injury. Make glasses just as integral as tools.

Be Aware of Surroundings

Look out for any tripping dangers like tools, cords, wood scraps that could lead to an accident when focused on a cut. Keep walkways clear.

Use Tools as Intended

Misusing a chisel as a screwdriver or over-extending a small saw can damage the tool or lead to mishaps. Learn each tool’s intended uses.

Don’t Force Tools

Forcing dulled blades requires physical exertion that can lead to slips, uneven cuts, and damage. Keep tools sharp.

Keep Tools Sharp and Clean

Sharp tools function best, are safer, and require less effort. Regular sharpening and cleaning prevents problems.

Make Several Light Passes

Removing a little material over several gradual passes gives you more control compared to hacking away. It also reduces strain.

Use a Workbench

A sturdy workbench keeps your workpiece securely in place as you saw, chisel, plane, and shape it. Essential for control and accuracy.

Master Your Grip

How you grip and control the tool is key. Choke up on the handle for fine work. Relax your grip to let the tool do the work. Practice and experiment.

Learning to use your hand tools safely, gently, and precisely takes patience and experience. But mastery will come with good habits and hours at the workbench.

Sharpening Hand Woodworking Tools

A sharp edge is imperative for hand woodworking tools to function as intended. Dull tools make work difficult and lose precision. While many modern planes and chisels come with factory sharpened blades ready to work, edges do degrade over time and need periodic re-sharpening. Here are some methods:

Sandpaper

Wrapping various grits of sandpaper around a block is an easy way to work a quick edge back onto tools. Start coarse and work up to finer grits. Can be done anywhere.

Waterstones

Natural and artificial waterstones can put an incredibly fine, polished edge on blades. Soak stone, then rub blade on stone in circular motions from coarse stone to fine. Honing guide helps.

Grinder

A slow speed grinder with a coarse wheel gently removes metal to reshape the edge. Quench in water to avoid losing temper. Follow by honing on stones or sandpaper.

Strops

After sharpening, a leather strop coated in polishing compound can refine the edge down to a mirror-like finish for a razor sharp edge with minimal metal removal.

Sharpening is a rabbit hole of techniques to master, but a basic system with a couple stones and a strop is enough to maintain sharpness. Take tools to stones periodically for quick tune-ups.

Beginner Woodworking Projects

Once you have assembled a starter set of hand woodworking tools, it’s time to put them to use on your first projects. The key with beginner projects is to start simple – focus on mastering your tools before tackling complex builds. Here are some beginner-friendly projects:

Cutting board

A simple rectangular cutting board lets you practice sawing and planing a flat panel square. Choose an inexpensive hardwood like maple to work with.

Box

Boxes teach precise layout, square corners, hinge installation, and fitting a lid. Start with a simple keepsake box before moving onto more elaborate cases and chests.

Mallet

Turn a piece of scrap lumber into a custom wood mallet to use when chiseling and hammering. Focuses on basic mallet shaping using gouges, rasp, and sandpaper.

Small shelf

Design and build a simple wall shelf with 1×4 pine boards or similar. Cuts are mainly square cross cuts. Teaches measuring, marking, assembly.

Birdhouse

A great project for practicing basic hand tool techniques. Focus on accurate wood joining and simple decorative elements. Leave a face panel off to see inside.

Part of the reward of woodworking is bringing an object into being after starting with raw materials. Don’t be over-ambitious at first. Simple utilitarian projects will teach you your tools.

Conclusion

While power tools have their place in efficient woodworking, hand tools should be the foundation of every workshop. Hand planes, chisels, saws, and more give you control over your materials and precision in crafting furniture and carpentry.

Learning hand tool woodworking does require patience. But persistence and regular practice will quickly reward you with growth in skills and confidence. Before long, you will reach for a hand plane or dovetail saw for those tasks where they excel.

If this guide has inspired you to start exploring hand tools, be sure to take small steps at first. Let your growing collection of tools match your skills. Most importantly, know that mastering hand woodworking tools to create lasting, meaningful objects is one of the most rewarding crafts. So enjoy the journey.

Here are 3 relevant additional links for more information:

https://www.rockler.com/learn/easy-projects-for-beginning-woodworkers

Rockler’s guide for beginning woodworkers with tips on starting out.

https://www.popularwoodworking.com/tools/the-core-hand-tools/

Popular Woodworking’s advice on buying your first hand tools.

https://www.instructables.com/Scrap-Wood-Shooting-Board-Hand-Tool-Woodworking-fo/

Instructables’ woodworking tutorial for beginners with project ideas.