- Introduction to Selecting the Best Woodworking Tools

- Essential Woodworking Tools for Beginners

- Advanced Tools for Intermediate and Expert Projects

- Understanding Woodworking Safety When Using Tools

- The Role of Measuring, Gauging, and Project Planning

- Tips for Cost-Effective Woodworking

- Identifying and Troubleshooting Common Woodworking Challenges

- Techniques and Tools for Specialized Woodwork

- Finalizing Projects with the Right Finishes

- Finding Motivation and Inspiration for Your Next Project

Introduction to Selecting the Best Woodworking Tools

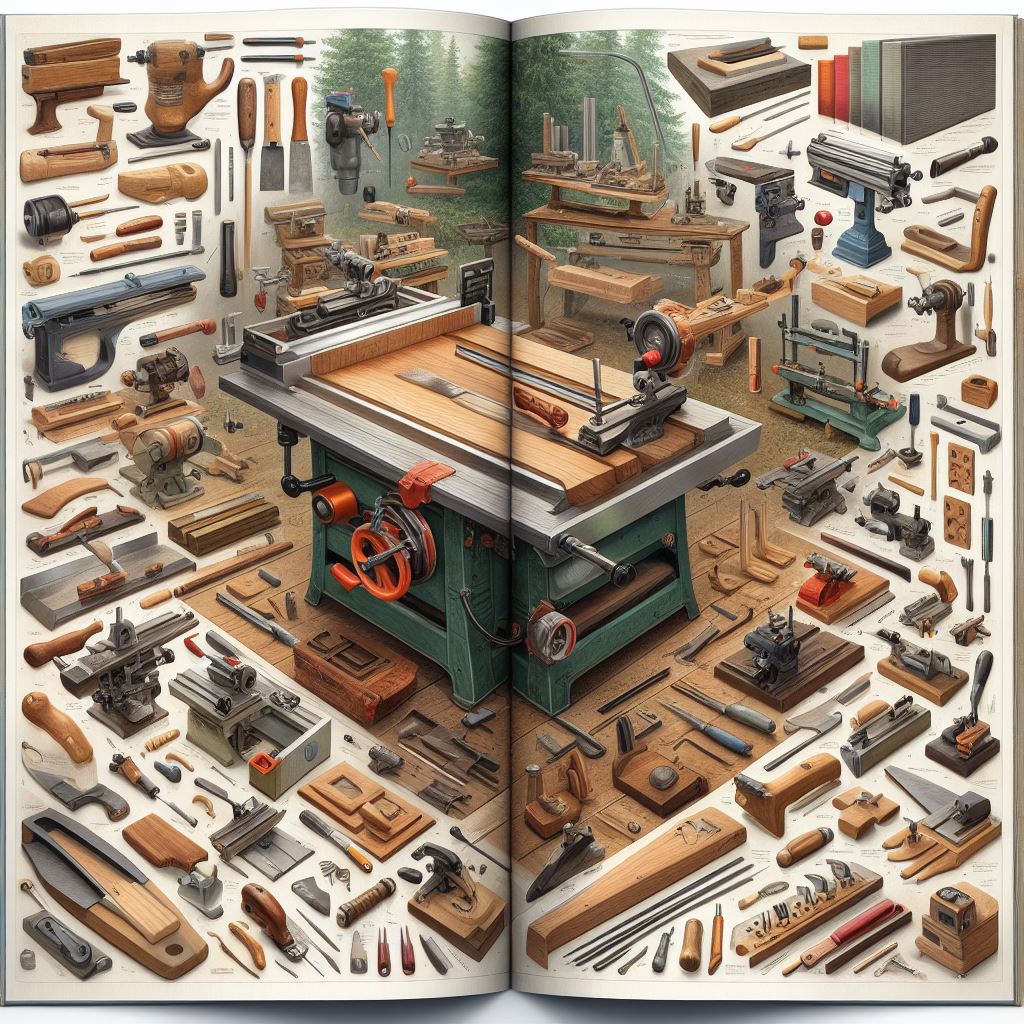

Embarking on woodworking projects brings with it the necessity to have an array of tools that suit various tasks. This introductory section will establish the foundation on how to approach the selection of woodworking tools, emphasizing not only the importance of choosing the right tool for the project at hand but also considering safety, functionality, and craftsmanship. From hand tools like chisels and saws to power tools such as drills and sanders, finding the appropriate equipment can be a challenge, especially for those new to the craft. Understanding the use cases and limitations of each tool can help ensure that woodwork is not only a creative and enjoyable endeavor, but also a safe one. This will prepare readers for a comprehensive journey through the critical aspects of selecting tools, from understanding different woodworking techniques to maintaining the tools you have. Regardless if one is a seasoned professional or a novice hobbyist, this guide will shed light on the essentials of tool selection and set the stage for crafting projects with confidence and expertise.

| Key Takeaways | Description |

|---|---|

| Tool Selection | Choose the right tool for each task, considering safety, functionality, and craftsmanship. |

| Beginner’s Toolkit | Start with basic hand tools like hammers, saws, screwdrivers, and learn the fundamentals. |

| Advanced Equipment | As skills improve, invest in power tools like routers and lathes for intricate work. |

| Woodworking Safety | Prioritize safety by learning tool operation, wearing protective gear, and maintaining a tidy workspace. |

| Measuring and Planning | Use accurate measuring and gauging tools and plan thoroughly for project success. |

| Cost-Effective Strategies | Invest in versatile tools, maintain them well, buy materials wisely, and enhance skills to save money. |

| Troubleshooting Challenges | Learn to identify and fix common issues, from wood imperfections to tool malfunctions. |

| Specialized Techniques | Explore and master advanced woodworking techniques with the appropriate tools. |

| The Right Finish | Select and apply proper finishes to protect and enhance the quality of the project. |

| Motivation and Inspiration | Find creative inspiration from a variety of sources and maintain motivation through learning and growth. |

Essential Woodworking Tools for Beginners

When venturing into the world of woodworking, having the right tools can dramatically influence both the process and the end result of your projects. Beginners in woodworking start by learning the ropes, which includes building a fundamental toolkit designed to cope with a broad range of tasks. The cornerstone of a beginner’s toolbox should comprise of hand tools such as hammers, saws, chisels, screwdrivers, and measuring tapes—tools that teach the fundamentals of woodworking and provide a tactile feel for the material.

Focusing on what constitutes a basic toolkit should revolve around the types of projects a beginner intends to undertake. For those interested in woodworking basics, projects such as simple boxes, shelves, or even basic DIY furniture projects are great for honing skills. Each tool should be selected for its ability to perform necessary cuts, joins, and finishes, starting with safety as a primary consideration.

It’s crucial for novices to understand that while the temptation might be to buy inexpensive tools to save on cost, investing in higher-quality tools can make a significant difference in ease of use, safety, and end results. Moreover, knowing when to use which tool also underlines the need for proper guidance and education, which can be acquired from resources such as woodwork basics.

Once the basic toolkit is established, maintenance becomes a key factor in ensuring longevity and reliability of tools. Sharpening blades, cleaning off rust, and keeping everything organized not only save time but also reduce the risk of accidents. As these foundational tools become second nature in their use, beginners can gradually expand their collection, keeping pace with their evolving skills and the complexity of their woodworking projects.

Advanced Tools for Intermediate and Expert Projects

For woodworkers who have transcended the beginner phase, a new range of more advanced tools beckons. These tools build upon the foundation laid by basic hand tools, facilitating more sophisticated and intricate forms of woodworking. Intermediate and expert-level projects often require the precision and power of specialized equipment such as routers, joiners, planers, and lathes. These tools can be used for detailed carving, joinery, shaping edges, and creating decorative patterns that are hallmarks of skilled craftsmanship.

Those interested in furthering their abilities with intermediate woodworking plans will need to familiarize themselves with the nuances of each advanced tool. Quality power tools can significant enhance the efficiency of tasks like cutting dados, creating mortise and tenon joints, or turning wood on a lathe. For intricate power tools woodworking projects, such as crafting a custom-built furniture piece or sculpting a detailed wooden figurine, the right power tools are indispensable.

However, with the enhanced capabilities of these tools comes a greater need for understanding their operation and inherent risks. Proper safety precautions must be rigorously observed, with users adhering to manufacturers’ guidelines and wearing appropriate protective gear. Woodworkers must also be vigilant about maintaining their tools, ensuring blades are sharp, batteries are charged, and any wear and tear is promptly addressed.

The investment in such tools should be considered carefully, taking into account the user’s skill level, the frequency of use, and the types of projects they aspire to complete. Owning a well-equipped workshop can provide immense satisfaction and professional-grade results, but only when tools are selected with intention and insight.

Understanding Woodworking Safety When Using Tools

Working with wood is a rewarding but potentially hazardous activity. Safety must always be the number one priority whenever using woodworking tools. Whether you are using a hand-held chisel or a high-powered table saw, understanding how to operate your tools safely is essential. This not only includes knowing how to use each tool properly but also wearing the right protective gear, such as safety glasses, ear protection, and dust masks to shield against sawdust and other particles.

Every woodworker, from beginners to experts, must familiarize themselves with woodworking safety tips for power tools. It’s vital to read and adhere to the manufacturer’s guidelines before operating any machinery, and be aware of any specific safety procedures related to the tools in use. Also, ensure that your work area is well-organized and free of any unnecessary clutter that could be a trip hazard or obstruct your ability to operate tools safely.

While focusing on the task at hand, it’s also important to have an understanding of fire prevention and know the emergency procedures for your work area. Woodworking safety should encompass the broader scope of being prepared for unexpected events, including fires, which can be a potential risk with sawdust accumulation and flammable materials. Ensure you have clear access to fire extinguishers and understand the protocols for evacuating safely in the event of an emergency.

Investing time in learning safety practices is crucial. The guidance provided in the fire prevention and emergency procedures guide could be life-saving. By staying vigilant and following proper safety procedures at all times, woodworkers can reduce the risk of injury and create a safe working environment, allowing them to continue their craft with peace of mind.

The Role of Measuring, Gauging, and Project Planning

Woodworking is both an art and a science, with accurate measuring and gauging acting as critical components of any project. A detailed plan, complete with precise measurements, is the foundation upon which successful woodworking is built. This level of preparation is key in minimizing material waste and ensuring that each piece fits together seamlessly, resulting in a professional finish.

The importance of woodworking measuring and gauging techniques cannot be overstated. From the initial design to the final assembly, every cut must be carefully calculated and executed. Utilizing tools like calipers, angle finders, and marking gauges greatly enhances accuracy, while a reliable tape measure and a sturdy ruler are indispensable staples in every woodworker’s toolkit.

This section will bridge the gap between a promising idea and a remarkable end product by emphasizing the role of meticulous project planning. To ensure a project’s success, planning must extend beyond a sketch on paper—it requires in-depth knowledge of the wood’s properties, the tools required for processing it, and the sequence of operations to bring the vision to life.

Those who practice thorough planning will find their projects are often more efficient and encounter fewer setbacks, as each step of the process has been contemplated and mapped out. Moreover, a well-considered plan also accommodates for potential issues, allowing for swift and effective solutions should they arise. The guidance drawn from resources such as woodworking plans: how to create can transform ideas into finished projects that stand as testaments to precision and craftsmanship.

Tips for Cost-Effective Woodworking

Woodworking can be an expensive hobby or business, especially when it comes to purchasing and maintaining the right tools for the job. However, with strategic planning and some savvy tips, you can engage in woodworking in a cost-effective manner. This section will highlight several woodworking cost-saving tips that can help woodcrafters stretch their dollars without compromising on the quality of their projects or safety standards.

One fundamental way to be cost-effective is to invest in multi-purpose tools that can perform a variety of tasks. Instead of buying a unique tool for each specific job, look for versatile equipment that can replace two or more specialized tools. For example, a good-quality table saw can often serve the purpose of several other tools if you use the right accessories and jigs.

Another key to saving money in woodworking is to maintain and care for your tools properly. Well-maintained tools last longer, perform better, and ensure your safety. Regularly cleaning, sharpening, and calibrating your tools will help prevent the need for expensive replacements or repairs. Keeping up with a woodworking tool maintenance schedule could be as important as the project execution itself.

When it comes to materials, purchase wisely. Buy lumber in bulk if you know you’ll use it, but be careful not to stockpile more than you need, as excess material costs money and can warp or degrade over time. Additionally, consider using reclaimed or recycled wood, which not only can save you money but also adds character to your projects and is better for the environment.

Lastly, enhance your skills through continued learning and practice. The more skilled you become, the more efficiently you’ll use your materials and tools, leading to less waste and fewer mistakes that can be costly to rectify. Practice with less expensive woods and build up to more costly materials as you gain confidence and precision in your craftsmanship.

By adopting these cost-effective strategies, woodworkers can enjoy their craft without breaking the bank. Meticulous planning, wise investing in tools and materials, and consistent tool maintenance play a crucial role in keeping costs down while still producing high-quality and safe woodwork.

Identifying and Troubleshooting Common Woodworking Challenges

Throughout every woodworker’s journey, they are bound to encounter a variety of challenges, each serving as a learning experience and an opportunity to improve their craft. Identifying these obstacles early on can prevent unnecessary frustration and save valuable time and resources. This section will provide guidance on common woodworking challenges, suggesting practical solutions and tips for troubleshooting. By leveraging the information found within woodworking troubleshooting tips, woodworkers can minimize the impact of these hindrances and maintain a steady workflow.

One of the most frequent issues woodworkers face is dealing with imperfections in wood, such as knots, splits, or warping. These can potentially compromise the strength and aesthetics of the final product. Consulting resources on woodworking finishing troubleshooting can help address how to mask or incorporate these imperfections into the design, transforming them into unique features rather than flaws.

Tool-related complications such as dull blades, inaccurate cuts, or machine malfunctions also often arise. Properly maintained tools are less likely to present such issues, which is why adhering to a woodworking tool maintenance schedule is imperative. Furthermore, recognizing that even the most well-maintained tools can falter at times, it’s essential to know how to pinpoint the source of the problem and apply the correct solution promptly.

Finishing woes are another common challenge, whether it’s stain that won’t take evenly or a polyurethane coat that bubbles. By fully understanding the properties of the finishes being used and the conditions they require for proper application, many of these issues can be circumvented. Should problems arise in this area, woodworkers can benefit from revisiting the steps to ensure that surfaces were adequately prepared and the finish was applied correctly.

Ultimately, it is fundamental to adopt a mindset where woodworking mistakes are embraced as imperfections that add character and history to the creations. Each error presents an avenue for growth and development in the art of woodworking. By analyzing what went wrong and learning how to correct it, woodworkers can build resilience and expand their skill set, making them more adept for future projects.

Techniques and Tools for Specialized Woodwork

While conventional woodworking techniques serve as the backbone for many projects, specialized woodworking methods can take a woodworker’s craft to new heights. Techniques such as curving, bending, and inlay work allow for the creation of unique, eye-catching pieces that exhibit a high level of artistry. This section dives into these advanced techniques, with a spotlight on woodworking bending and curving techniques, and discusses the essential tools required to master such skills.

These specialized techniques often demand tools that are specific to the task. Steam bending wood, for example, requires not just a steam box but also forms and clamps to shape the wood as it cools. Similarly, intricate inlays might require delicate hand tools like specialized chisels and routers with precise bits to achieve the level of detail desired. Choosing the proper tools not only enhances the quality of the work but also ensures that the process is as efficient and safe as possible.

Maintenance of these tools is as crucial as their selection. A consistent woodworking tool maintenance schedule ensures that tools stay in top condition, reducing the likelihood of errors and accidents. Careful upkeep also maximizes the longevity of the tools, protecting the investment one has made into their woodworking arsenal. From sharpening blades to calibrating jigs, regular attention can keep these specialized tools ready at a moment’s notice.

Projects that thrive from such specialized techniques include carved wooden sculptures, custom furniture with organic shapes, and decorative woodwork that requires bending or twisting, like in scrap wood woodworking projects. The knowledge gained through the mastery of these techniques not only increases the scope of projects one can undertake but also provides an impressive showcase of a woodworker’s breadth of skills and attention to detail.

The art of woodworking is continually evolving, and by exploring these specialized areas, woodworkers can remain at the forefront of the craft. Whether bending a piece of oak into a graceful arc or intricately inlaying mother-of-pearl into mahogany, the advanced techniques and appropriate tools for specialized woodworking enable the transformation of raw materials into works of art.

Finalizing Projects with the Right Finishes

After investing time, effort, and resources into a woodworking project, the application of the final finish is crucial to its overall success and longevity. The right finish not only enhances the aesthetic appeal of the wood but also protects it from environmental factors and daily wear and tear. This segment will guide readers through the various types of finishes available, highlighting the advantages of woodworking finishing with natural oils, which can provide a beautiful and durable surface grace to just about any project.

Choosing an appropriate finish depends on the project’s intended use, the type of wood, and the desired look. For projects that come into close contact with food, such as cutting boards or dining tables, finishes that are marked as food-safe, such as certain oils or waxes, are a priority. Whereas for items that will be subjected to the elements, such as outdoor furniture, a more robust, weather-resistant finish like a polyurethane or varnish may be more suitable.

Proper application of finishes is a skill in itself, often requiring a keen eye and a steady hand. Each type of finish—be it wax, oil, lacquer, or stain—demands a specific application method, whether that’s wiping, brushing, or spraying. Factors such as temperature, humidity, and the condition of the wood surface will also affect the application process and ultimately, the final result. The contrasting requirements for projects designed for small spaces woodworking projects may differ from those made to stand out in more spacious areas, further influencing the finish selection.

It is essential to be mindful of the dry times and the number of coats needed, which can vary widely amongst different finish types. Sanding between coats, when required, should be done with care to avoid scratches that could mar the surface. The patience and precision with which finishes are applied are usually rewarded with a sublime end product that stands the test of time.

Woodworking finishes not only improve the visual and tactile quality of wood projects but also serve as a protective barrier. An appropriately chosen and expertly applied finish can resist moisture, heat, abrasion, and other environmental stresses, preserving the natural beauty of the wood and the hard work put into the craftsmanship.

Finding Motivation and Inspiration for Your Next Project

Even the most passionate woodworkers can face a creative block or lack of motivation from time to time. Finding new ideas and staying inspired is crucial for maintaining the joy and fulfillment that comes with woodworking. Whether you’re looking for your next big project or simply need to rekindle your love for the craft, there are abundant sources of inspiration to tap into.

Exploring the rich history and diversity of woodworking inspiration from arts and crafts movements can open your eyes to styles and techniques you may not have considered before. The intricacies of joinery from Japanese woodworking, the simplicity of Shaker designs, or the organic forms of Scandinavian woodcraft are all examples that can spark new ideas and approaches to your work.

Visiting galleries, participating in workshops, or even scrolling through online communities can offer a fresh perspective on what’s possible with wood. With a little exploration, you may find that a certain style or technique resonates deeply with you, pushing you to try something new. Sometimes, the best motivation comes from stepping outside your comfort zone and embarking on projects that challenge your current skill set.

Moreover, daily surroundings and nature itself are often overlooked treasure troves of inspiration. The curve of a branch, the grain of wood cut by a lumber mill, or the joinery in antique furniture pieces—all have the potential to spark the imagination. Keep a sketchbook or digital note-taking device handy to jot down ideas as they come to you; inspiration can strike at any moment.

For those who need a more structured approach to finding motivation, woodworking inspiration and motivation resources offer guidance on setting goals, creating a conducive workspace, and cultivating the discipline needed to start and finish projects. They also emphasize the importance of celebrating your successes and learning from any mishaps along the way.

Ultimately, the key to ongoing motivation and inspiration lies in your ability to connect with the work, continually learn and grow, and appreciate the process as much as the product. Remember that every piece you create, no matter how simple or complex, is a reflection of your journey as a woodworker. With each project you complete, you’re not only shaping wood, but also molding your future as a craftsman.