Woodworking is a rewarding hobby and profession, but also carries risks of injury. By following proper safety procedures and wearing protective equipment, you can help prevent accidents from tools like table saws, routers, drill presses, and more in your workshop.

This article provides top tips on identifying hazards, developing safe working habits, using tools properly, and creating a safety culture to help you avoid common woodworking wounds. Follow these essential ways for Preventing Common Woodworking Injuries with tips to protect yourself and others.

Key Causes of Workshop Accidents and Injuries

Woodworking mishaps often result from:

- Complacency around dangerous tools

- Distraction or fatigue

- Lack of training on equipment

- Missing machine guards and unsafe working zones

- No personal protective equipment (PPE)

- Poor housekeeping creating tripping hazards

Develop a Safety Mindset

Cultivating a culture of safety is the first step to reducing accidents through heightened awareness and caution in your shop. Safety should become second nature through good habits.

Key Tips for Fostering a Safety Culture

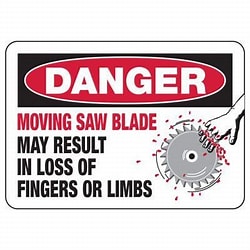

- Place highly visible warning labels and signs around your workspace

- Take the time to identify hazards and risks before operating tools or finishing cuts

- Use lockout/tagout devices when servicing or repairing machinery

- Follow manufacturer operating guidelines for all tools and materials

- Invest in upgraded safety equipment like push sticks, holders, anti-kickback devices

- Encourage anyone entering your shop to wear PPE without exception

- Lead by example – act safely around activated equipment at all times

As part of your safety mindset, understand the most frequent woodworking wounds and how to avoid them.

Most Common Woodshop Accidents and Prevention Tips

While no two accidents are the same, many share common causes. Prepare yourself through education and vigilance.

1. Table Saw Injuries

15% of reported workshop accidents involve table saws, making them the most dangerous fixed power tool. Common table saw injuries include:

- Lacerations – Kickback from cutting wood shoots projectiles rapidly toward the operator

- Amputations – Fingers/hands get trapped contacting the blade during rip or cross cuts

Follow these table saw safety rules:

- Wear cut-resistant gloves and safety glasses

- Avoid loose clothing and jewelry that could catch on the spinning blade

- Keep blade guards installed and working properly

- Stand out of line with the blade during cuts

- Use push sticks, blocks, holders to keep hands away from the blade

- Unplug the saw before clearing jams or changing blades

- Avoid fatigue and distractions – stay alert!

2. Wood Dust Hazards

Constantly working around fine particle dust, as from sanding or sawing, increases your chances of:

- Asthma attack triggers

- Sinus irritation

- Eye, nose and throat discomfort

- Respiratory diseases like chronic bronchitis

Minimize risks by:

- Using dust collection systems attached to equipment

- Wearing NIOSH N95 rated masks

- Adding ventilation like air filtration units or exhaust fans

- Using wet methods of dust suppression when possible

- Cleaning the shop frequently to avoid buildup on surfaces

3. Noise-Induced Hearing Loss

- OSHA reports 50% of woodworkers experience significant hearing damage from loud tools

- Common workshop noise ranges from 110-130 decibels, well above the pain threshold

- Extended exposure can lead to irreversible hearing loss and persistent ringing ears (tinnitus)

Protect your hearing with:

- Ear plugs and noise-reduction earmuffs (worn together)

- Taking regular breaks away from noisy machinery

- Getting annual hearing tests to monitor for early signs of loss

- Choosing quieter tools like ISO type 1 saws under 100 db

- Soundproofing your workshop walls/ceiling or working outdoors

4. Slip, Trip and Fall Incidents

Cluttered work zones lead to tripping on:

- Wood scraps

- Electrical cords

- Tools and supplies blocking walkways

Prevent falls by:

- Removing waste frequently

- Coiling/suspending cords overhead

- Storing materials neatly on shelves or in cabinets

- Having good lighting in all areas

- Putting non-slip mats down on hard floors

- Securing rugs and clearing paths

- Keeping floors smooth but not slippery

Develop Safe Equipment Habits

Beyond a general safety focus, methodically control hazards with proper work techniques. Follow manufacturer instructions and keep machine guards in place during use.

Table Saws

- Make shallow finish cuts at the end to avoid kickback

- Feed material straight through the blade slowly and smoothly

- Stand securely balanced on two steady feet, not leaning

- Require saw blade to stop fully before touching it

Sanders and Routers

- Always grip with two hands for maximum control

- Adjust belts, bits for snug fit to avoid flying off

- Position cords safely to avoid pulling device unexpectedly

Drill Presses and Jointers

- Secure workpieces in vise or clamps to prevent spinning

- Don’t wear gloves that could get grabbed by the spinning bit

- Make multiple shallow passes for smooth cuts without jamming

Develop Personal Safe Habits

Your individual behavior in the workshop directly impacts your safety. Avoid harm by being attentive, thoughtful and cautious at all times.

- Never operate tools when tired, rushed or distracted

- Tie back long hair and avoid loose sleeves or jewelry

- Wear snug safety glasses, hearing protection, dust mask and sturdy shoes

- Slow down and focus when feeling frustrated or irritated

- Plan work ahead of time and don’t improvise unsafely

- Take breaks when feeling overexerted, stressed or having difficulty concentrating

- Clean tools after using and put items away to maintain order

As skills advance, don’t become overconfident – continue safety protocols. Stay present in the moment when running equipment. Have and learn to use safety accessories like push sticks.

Create a Safety Action Plan

Use this checklist to inspect your shop and procedures to further boost safety:

🔸 Ensure adequate workshop lighting, ventilation, exits

🔸 Check electrical systems & cords to NEC standards

🔸 Secure rugs, clear walkways & post warning signs

🔸 Mount fire extinguishers & first aid kits visibly

🔸 Establish eye wash stations & marking safe standing zones

🔸 Frequently clean built-up dust using HEPA vacuums

🔸 Schedule machine maintenance checks

🔸 Review tool manuals & train on proper use

🔸 Document shop rules & emergency contacts clearly

🔸 Join woodworking forums to ask safety questions

Conclusion

Make injury prevention a regular priority rather than an afterthought. Apply the tips in this article to analyze hazards, upgrade safety equipment, improve workspace layout, sharpen skill techniques and embrace precautionary methods.

Safety ultimately requires vigilance from all workshop users. Build open communication, share safety learnings, enforce PPE use for anyone entering, and lead by modeling secure habits constantly.

Investing a bit more attention to create a clean, hazard-free area where you and others feel comfortable prevents the outsized cost of accidents over the long run. You can feel pride keeping safety as the foundation of your craft.

Key Takeaways

- Adopt safety mindset through hazard ID and risk reduction

- Prepare for the most frequent woodworking accidents

- Follow manufacturer tool guidelines

- Use PPE like dust masks, ear protection, gloves

- Improve work habits – precision over speed

- Clean and organize workspace areas

- Join safety training workshops and forums

Frequently Asked Safety Questions

1. Should I buy upgraded safety accessories for my power tools?

Yes, it’s wise to invest in push sticks, jigs, holders and guards that reduce contact injuries beyond built-in protections. Features like anti-kickback pawls and riving knives greatly improve table saw safety.

2. What are recommended ways I can reduce noise exposure?

Use foam disposable or reusable earplugs AND noise-blocking earmuffs together. Take frequent breaks and rotate tasks away from constant loud machinery. Soundproof your shop interior walls, doors and ceiling.

3. Is a dusty shop inevitable or can I control wood particles?

Proper dust collection makes a major difference – equip machines with microfiltering systems, ventilate adequately and wear N95 masks when needed. Controlling dust takes effort but prevents long-term lung damage.

4. Should I create physical barriers or markings around tools?

Yes, set up safety buffers in busy zones by machines to prevent contact injuries and falls. Brightly paint safe standing work areas on the floor. Post highly visible warning labels on tools themselves.

5. What are quick ways to prevent slips and falls in my workspace?

Coil or suspend cords off the ground, secure loose rugs on the floor, add rubber mats in heavy traffic zones, improve lighting in dim corners, promptly clean spills and debris and store materials on shelves to open clear paths.

6. How often should I replace key safety gear?

Replace dust masks after 8 hours of use or when breathing becomes more difficult. Swap disposable earplugs frequently when worn or visibly dirty. Check fire extinguishers, first aid supplies, PPE for wear monthly and replace anything expired or damaged.

7. Is it safe for children or teenagers to use my workshop when supervised?

Generally no one under 18 should access tools, even with guidance. However, organizations like Woodworking for Kids offer youth safety programs – when well controlled by experts, this hands-on learning has value.