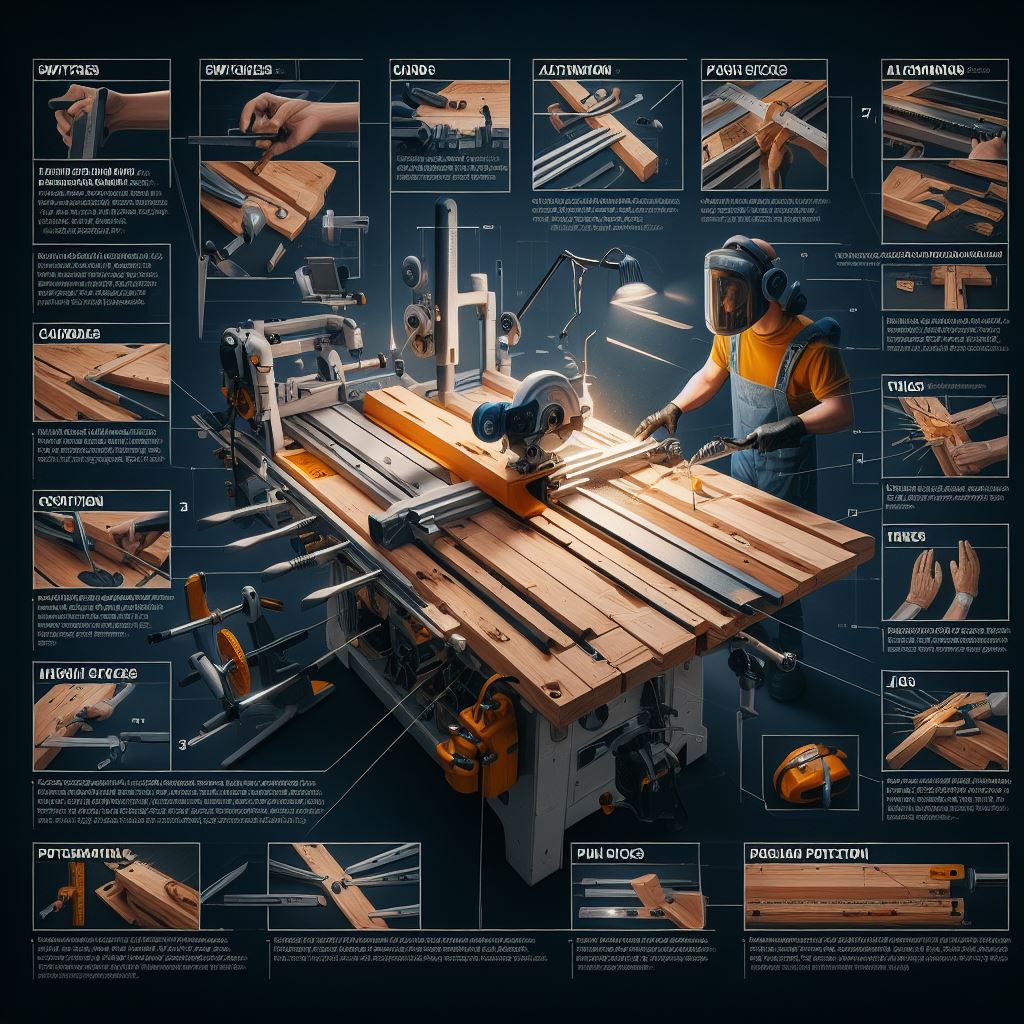

In this comprehensive guide, we’ll explore the essential aspects of woodworking tool safety, providing you with the knowledge and techniques to protect yourself while enjoying your craft. Woodworking is a rewarding and creative hobby that allows you to bring your imagination to life through the art of crafting with wood. However, it’s crucial to remember that working with powerful tools and machinery comes with inherent risks.

Key Takeaways

| Safety Category | Top Tips | Why It Matters |

|---|---|---|

| Personal Protective Equipment | Use safety glasses, ear protection, dust mask | Prevent eye injuries and lung irritation |

| Safe Tool Handling | Secure workpieces, don’t force tools, maintain sharpness | Prevent binding and kickback accidents |

| Workshop Conditions | Efficient dust collection, adequate lighting, clear access paths | Reduce risk of respiratory issues, fatigue, and slips |

Understanding the Importance of Tool Safety

Before diving into specific safety measures, it’s vital to grasp why tool safety is paramount in woodworking. According to the U.S. Consumer Product Safety Commission, over 30,000 table saw injuries occur annually, with many more incidents involving other woodworking tools. By prioritizing safety, you not only protect yourself from potential harm but also ensure a more enjoyable and productive woodworking experience.

General Safety Practices

Personal Protective Equipment (PPE)

Your first line of defense against woodworking hazards is proper personal protective equipment:

- Safety Glasses: Always wear ANSI-approved safety glasses to protect your eyes from flying debris. Consider goggles or a face shield for added protection during high-risk operations.

- Hearing Protection: Use earplugs or earmuffs to safeguard your hearing, especially when operating loud machinery like table saws or routers.

- Dust Mask or Respirator: Protect your lungs from wood dust and other airborne particles. For extensive work or when dealing with exotic woods, consider using a respirator.

- Proper Clothing: Wear close-fitting clothes to avoid getting caught in moving parts. Avoid loose jewelry, and tie back long hair.

- Sturdy Footwear: Closed-toe shoes with non-slip soles provide protection and stability in the workshop.

Workspace Safety

A safe working environment is crucial for preventing accidents:

- Cleanliness: Keep your workspace tidy and free of clutter. Regularly clean up sawdust and debris to prevent slips and fire hazards.

- Lighting: Ensure adequate lighting in your workshop to improve visibility and reduce the risk of accidents.

- Tool Storage: Store tools properly when not in use. Consider using wall mounts for woodworking to keep your workspace organized and tools easily accessible.

- Fire Safety: Have a fire extinguisher readily available and know how to use it. Be cautious with flammable materials and dust accumulation.

- First Aid Kit: Keep a well-stocked first aid kit in your workshop for minor injuries.

Power Tool Safety

Power tools significantly increase efficiency in woodworking but require extra caution:

Table Saw Safety

The table saw is one of the most versatile and potentially dangerous tools in a woodworking shop:

- Use the Guard: Always use the blade guard and splitter when possible. These safety features help prevent kickback and protect your hands.

- Push Sticks and Featherboards: Use push sticks for narrow cuts and featherboards to maintain pressure against the fence and table.

- Blade Height: Set the blade height so it’s just high enough to cut through the workpiece, reducing the exposed blade area.

- Stand Positioning: Stand to the side of the blade, not directly behind it, to avoid potential kickback injuries.

- Maintain Your Saw: Regularly check and maintain your table saw, ensuring the blade is sharp and properly aligned.

For more in-depth information on table saw usage and safety, check out this guide on unlocking the potential of your woodworking table saw.

Router Safety

Routers are versatile tools that require careful handling:

- Secure Workpieces: Always clamp your workpiece securely before routing.

- Bit Installation: Ensure router bits are properly installed and tightened before use.

- Feed Direction: Move the router against the bit’s rotation to maintain control and prevent climb-cutting.

- Speed Settings: Use appropriate speed settings for different bit sizes and materials.

- Let the Tool Stop: Wait for the router to come to a complete stop before setting it down.

Learn more about selecting the right router bits for your projects in this article on router bits for different materials.

Circular Saw Safety

Circular saws are portable and powerful, requiring careful handling:

- Blade Guard: Never disable or remove the retractable blade guard.

- Support the Work: Ensure proper support for the workpiece to prevent binding or kickback.

- Proper Grip: Maintain a firm grip with both hands on the saw’s designated handles.

- Blade Depth: Set the blade depth to just clear the thickness of the material being cut.

- Cutting Line: Keep the saw blade on the waste side of the cutting line to improve accuracy and safety.

Hand Tool Safety

While often considered safer than power tools, hand tools still require proper handling:

Chisel Safety

- Sharp Tools: Keep chisels sharp to reduce the force needed and improve control.

- Work Away from Your Body: Always direct the chisel away from yourself and others.

- Use Both Hands: Guide the chisel with your non-dominant hand while striking with your dominant hand.

- Proper Storage: Store chisels in a dedicated rack or with blade guards to protect the edges and prevent accidents.

For a comprehensive guide on chisel types and uses, visit a comprehensive guide to woodworking chisels: types and uses.

Handsaw Safety

- Secure Workpieces: Use clamps or a vise to hold the workpiece steady while sawing.

- Starting Cuts: Use your thumb as a guide to start the cut accurately and safely.

- Proper Technique: Use long, smooth strokes and let the saw do the work without excessive force.

- Storage: Store handsaws with blade guards or hang them securely to protect the teeth and prevent injuries.

Dust Collection and Respiratory Safety

Wood dust can be a significant health hazard in woodworking:

- Dust Collection System: Install and maintain an effective dust collection system in your workshop.

- Regular Cleaning: Clean your workspace regularly to minimize dust accumulation.

- Proper Ventilation: Ensure good ventilation in your workshop to reduce airborne dust particles.

- Respiratory Protection: Use appropriate dust masks or respirators, especially when working with exotic woods or generating large amounts of dust.

Electrical Safety

Electrical hazards are often overlooked in woodworking shops:

- Proper Wiring: Ensure your workshop has adequate electrical capacity and proper wiring for your tools.

- Ground Fault Circuit Interrupters (GFCIs): Use GFCI outlets in your workshop to protect against electric shock.

- Inspect Cords: Regularly check power cords for damage and replace them if necessary.

- Avoid Wet Conditions: Keep electrical tools and connections away from water and damp conditions.

Safe Material Handling

- Proper Lifting Technique: Use your legs, not your back, when lifting heavy materials or equipment.

- Ask for Help: Don’t hesitate to ask for assistance when handling large or awkward pieces.

- Use Carts or Dollies: Utilize material handling equipment to move heavy items safely.

- Storage: Store materials securely to prevent tipping or falling hazards.

Advanced Safety Techniques

Kickback Prevention

Kickback is a dangerous occurrence in woodworking, particularly with table saws and routers:

- Use Splitters and Riving Knives: These devices help prevent the wood from pinching the blade and causing kickback.

- Avoid Freehand Cuts: Always use fences or guides to control the workpiece’s movement.

- Maintain Control: Keep a firm grip on the workpiece and use push sticks or featherboards when appropriate.

Proper Tool Maintenance

Well-maintained tools are safer and more efficient:

- Regular Inspections: Check your tools regularly for signs of wear or damage.

- Keep Tools Sharp: Sharp tools require less force, reducing the risk of slips or loss of control.

- Follow Manufacturer Guidelines: Adhere to maintenance schedules and recommendations provided by tool manufacturers.

- Clean After Use: Clean tools after each use to prevent buildup of dust and debris, which can affect performance and safety.

Creating a Safety-First Mindset

Developing a safety-first approach to woodworking is crucial:

- Educate Yourself: Continuously learn about tool safety and best practices. Consider taking workshops or classes to improve your skills.

- Plan Your Work: Before starting a project, plan your cuts and processes to minimize risks.

- Stay Focused: Avoid distractions while working. Don’t operate tools when tired or under the influence of medications that may impair judgment.

- Teach Others: If you have apprentices or share your workshop, emphasize the importance of safety and lead by example.

Conclusion

Woodworking tool safety is an essential aspect of the craft that should never be overlooked. By implementing these safety practices and maintaining a vigilant approach to potential hazards, you can significantly reduce the risk of accidents and injuries in your workshop. Remember, a safe woodworker is a productive and happy woodworker. Prioritize safety in every project, and you’ll enjoy a long, rewarding journey in the world of woodworking.

Whether you’re a beginner starting with simple wooden crafts for kids or an experienced craftsman tackling profitable woodworking projects, always keep safety at the forefront of your mind. With the right precautions and knowledge, you can create beautiful pieces while protecting yourself and others in your workshop.

Here are 3 external links that would be help you maintain woodworking tool safety:

- For statistics on table saw injuries: U.S. Consumer Product Safety Commission – Table Saw Injuries https://www.cpsc.gov/s3fs-public/Table-Saw-Injuries-1.pdf

- For information on personal protective equipment standards: Occupational Safety and Health Administration (OSHA) – Personal Protective Equipment https://www.osha.gov/personal-protective-equipment

- For general woodworking safety guidelines: National Safety Council – Woodworking Safety https://www.nsc.org/community-safety/safety-topics/home-and-recreational-safety/woodworking-safety