Introduction

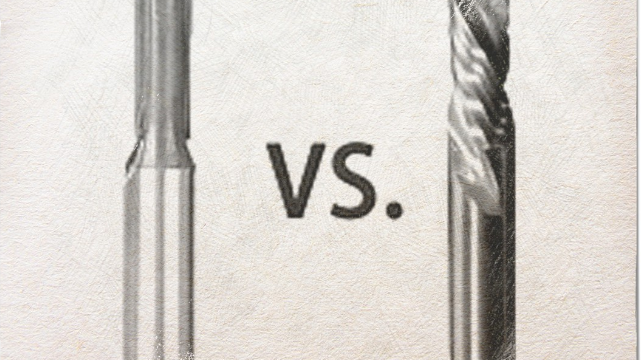

Every woodworker’s dream is to create flawless, professional-looking pieces that showcase their skill and attention to detail. However, achieving that level of perfection requires the right tools and techniques – and that starts with understanding the nuances of your router bits. Whether you’re crafting intricate designs or tackling straightforward projects, the choice between a straight bit and a spiral bit can make a world of difference.

Imagine running your router along the edge of a board, only to be met with a rough, splintered surface that ruins the clean lines you envisioned. Or perhaps you’ve experienced the frustration of a bit that clogs easily, slowing down your workflow and compromising the quality of your work. These are common issues that can be addressed by selecting the appropriate bit for the task at hand.

In this article, we’ll delve into the key differences between straight bits and spiral bits, empowering you to make informed decisions and elevate your woodworking game. By understanding their unique characteristics and applications, you’ll be able to tackle projects with confidence and achieve professional-grade results every time.

Key Takeaways:

- Straight bits are ideal for clean, precise cuts and trimming operations.

- Spiral bits excel at plunging and cutting end grain, reducing tear-out and splintering.

- The cutting action and chip removal mechanisms of each bit type impact their performance.

- Choosing the right bit can improve efficiency, quality, and safety in your woodworking projects.

- Factors like workpiece material, project requirements, and bit size should guide your selection.

Straight Bits: Precision and Clean Cuts

Straight bits, also known as straight router bits or straight cutting router bits, are the workhorses of the woodworking world. These bits feature a straight cutting edge with sharp, evenly spaced flutes that run parallel to the bit’s shaft. This design makes them well-suited for a variety of trimming and cutting operations where precision and a clean, smooth finish are paramount.

One of the main advantages of straight bits is their ability to create crisp, clean edges and profiles. Whether you’re routing dados, rabbets, or intricate patterns, these bits excel at producing precise cuts with minimal tear-out or splintering. This is particularly beneficial when working with solid wood or veneers, where a flawless finish is essential.

Straight bits are also highly versatile and can be used for a wide range of applications, including:

- Edge trimming: Trimming the edges of laminate countertops, veneers, or plywood sheets to achieve a clean, flush fit.

- Joinery: Creating precise mortise and tenon joints, dovetails, or box joints for strong, interlocking connections.

- Decorative routing: Cutting intricate designs, patterns, or inlays for added visual appeal.

- Drawer and cabinet making: Routing dadoes, rabbets, and grooves for shelves, drawers, and cabinet frameworks.

When using straight bits, it’s crucial to feed the workpiece at a consistent rate and avoid excessive force, as this can lead to tear-out or burning. Additionally, straight bits may not be the best choice for cutting end grain or plunging into the workpiece, as these actions can cause splintering or chipping.

Spiral Bits: Conquering End Grain and Plunging

While straight bits excel at precision routing, spiral bits, also known as up-cut spiral bits or compression bits, are designed to tackle end grain and plunging operations with ease. These bits feature a unique spiral or helical cutting edge that wraps around the body of the bit, creating a shearing action that slices through the wood fibers rather than tearing or chipping them.

One of the primary advantages of spiral bits is their ability to reduce tear-out and splintering, especially when cutting end grain or plunging into the workpiece. This is due to their spiral cutting action, which gradually severs the wood fibers, and their efficient chip removal mechanism, which clears away debris and prevents clogging.

Spiral bits are particularly useful for the following applications:

- End grain routing: Cutting across the end grain of wood, such as when creating mortises or tenons, without causing excessive tear-out or splintering.

- Plunging cuts: Plunging the bit directly into the workpiece to create mortises, pockets, or other recessed areas without damaging the surrounding surface.

- Solid surface routing: Working with solid surface materials like Corian or solid phenolic, where minimizing chipping and tear-out is essential.

- Cutting laminates: Routing through laminate countertops or other laminated surfaces without causing delamination or chipping.

While spiral bits offer superior performance for these specific tasks, they may not be the best choice for routing large areas or creating intricate profiles, as their cutting action can sometimes leave a slightly rougher surface than straight bits. Additionally, spiral bits tend to be more expensive than their straight counterparts.

Cutting Action and Chip Removal: The Key Differences

To better understand the differences between straight bits and spiral bits, it’s important to examine their cutting action and chip removal mechanisms. These factors play a crucial role in determining the quality of the cut, the level of tear-out or splintering, and the overall efficiency of the routing process.

Cutting Action:

- Straight bits: Straight bits employ a shearing action, where the sharp flutes slice through the wood fibers in a straight line. This action is ideal for creating clean, precise cuts and profiles, but can lead to tear-out or splintering when cutting end grain or plunging into the workpiece.

- Spiral bits: Spiral bits use a slicing or shearing action combined with a spiral cutting edge that gradually severs the wood fibers. This cutting action reduces tear-out and splintering, particularly when cutting end grain or plunging into the material.

Chip Removal:

- Straight bits: The straight flutes on these bits allow for efficient chip removal when routing along the grain or making through cuts. However, when cutting end grain or plunging, chips can accumulate and clog the bit, leading to potential burning or rough surfaces.

- Spiral bits: The spiral cutting edge and helical flutes on these bits create an Archimedean screw effect, continuously lifting chips and debris away from the cutting area. This efficient chip removal system helps prevent clogging and overheating, even when cutting end grain or plunging.

Understanding these mechanisms will help you choose the right bit for the job, ensuring optimal results and a smoother, more efficient routing experience.

Choosing the Right Bit: Factors to Consider

While both straight bits and spiral bits have their strengths, selecting the appropriate bit for your project can make a significant difference in the quality of the final product, as well as your overall workflow and safety. Here are some key factors to consider when choosing between a straight bit and a spiral bit:

- Workpiece material: Different materials may require different bit types. For example, solid wood may benefit from a spiral bit when cutting end grain, while laminate surfaces often perform better with straight bits.

- Project requirements: Assess the specific needs of your project. If you’re creating intricate profiles or working with veneers, a straight bit may be the better choice. If you’re cutting mortises, plunging, or routing end grain, a spiral bit may be more suitable.

- Bit size: Larger bits, particularly those with diameters over 1 inch, may benefit from the added strength and chip removal capabilities of spiral bits, especially when plunging or cutting end grain.

- Tear-out and splintering: If you’re concerned about tear-out or splintering, particularly when working with end grain or plunging into the workpiece, a spiral bit is typically the safer option.

- Surface finish requirements: For projects that demand a smooth, flawless surface finish, straight bits may be the better choice, as their cutting action can leave a cleaner edge than spiral bits.

- Feed rate: Straight bits generally perform better when fed at a consistent rate, while spiral bits can handle more aggressive feed rates due to their efficient chip removal system.

Remember, there is no one-size-fits-all solution. The best bit choice will depend on the specific requirements of your project and the materials you’re working with. Don’t hesitate to experiment with different bit types and sizes to find the optimal combination for your woodworking needs.

Mastering Bit Selection: Tips and Best Practices

To get the most out of your router bits and achieve professional-quality results, follow these tips and best practices:

- Read the manufacturer’s recommendations: Consult the manufacturer’s guidelines for each bit to understand its intended use, recommended materials, and any specific precautions or techniques.

- Consider the grain direction: When routing end grain, always use a spiral bit to minimize tear-out and splintering. For routing along the grain or cross-grain, a straight bit may be more suitable.

- Match the bit to the material: Different materials may require different bit types. For example, when working with solid surface materials like Corian, a spiral bit is often the better choice to prevent chipping.

- Maintain proper feed rate: Feed the workpiece at a consistent, controlled rate to avoid overloading the bit or causing burning. Spiral bits can generally handle faster feed rates than straight bits.

- Start with a smaller diameter: When plunging or cutting end grain, start with a smaller diameter bit and work your way up to the desired size, reducing the risk of tear-out or overloading the bit.

- Use appropriate safety gear: Always wear eye protection, hearing protection, and a dust mask or respirator when routing to ensure your safety.

- Keep bits sharp and well-maintained: Dull or damaged bits can lead to poor cuts, increased tear-out, and potential safety hazards. Regularly inspect and sharpen your bits, or replace them as needed.

- Experiment and observe: Don’t be afraid to try different bit types and sizes on scrap pieces to observe their performance and develop a feel for their unique characteristics.

By following these tips and best practices, you’ll not only maximize the performance of your router bits but also ensure a safer and more enjoyable woodworking experience.

FAQs: Addressing Common Concerns

What is the difference between an up-cut and down-cut spiral bit?

Up-cut spiral bits are designed for plunging and cutting end grain, as they lift the chips upwards and away from the workpiece, reducing tear-out. Down-cut spiral bits are better suited for routing along the grain and creating a smoother surface finish, as they push the chips downwards into the workpiece.

Can I use a straight bit for plunging or cutting end grain?

While it’s possible to use a straight bit for plunging or cutting end grain, it’s not recommended as it increases the risk of tear-out and splintering. Spiral bits are designed specifically for these tasks and offer superior performance and safety.

Are spiral bits more expensive than straight bits?

Generally, yes. Spiral bits tend to be more expensive than their straight counterparts due to their more complex design and manufacturing process.

How do I determine the right bit size for my project?

Consider the depth of cut required, the size of the workpiece, and the size of the router you’ll be using. It’s generally recommended to use the smallest bit size that can achieve the desired results, as larger bits can be more challenging to control and may require more power.

Can I use the same bit for different materials?

While some bits can be used on a variety of materials, it’s generally recommended to select a bit specifically designed for the material you’re working with. This will ensure optimal performance and safety.

How do I properly store and maintain my router bits?

Store router bits in a dry, protected environment, such as a bit case or drawer. Regularly clean and inspect them for wear or damage, and sharpen or replace them as needed. Proper maintenance can significantly extend the life of your bits.

What are some common safety precautions when using router bits?

Always wear appropriate safety gear, including eye and hearing protection, and a dust mask or respirator. Follow the manufacturer’s guidelines, secure the workpiece properly, and maintain a firm grip on the router. Never force the bit or exceed its recommended feed rate.

External Resources and Video

For further exploration of router bits and woodworking techniques, check out these external resources:

- – A detailed article from Wood Magazine covering the different types of router bits and their applications.

- Choosing the Right Router Bit for Your Project – An informative article from Fine Woodworking magazine on selecting the appropriate router bit based on your project needs.

Additionally, this YouTube video from Straight Bits vs. Spiral Bits for Woodworking provides a visual demonstration of different router bit types and their usage:

YouTube Video: Router Bit Types and Applications

Conclusion

In the world of woodworking, the choice between a straight bit and a spiral bit can make a significant impact on the quality of your work and the efficiency of your workflow. By understanding the unique characteristics and applications of each bit type, you’ll be better equipped to tackle a variety of projects with confidence and precision.

Straight bits excel at clean, precise cuts and trimming operations, making them ideal for creating intricate profiles, edge trimming, and joinery tasks. On the other hand, spiral bits shine when it comes to plunging, cutting end grain, and minimizing tear-out and splintering, particularly when working with solid surface materials or laminates.

Remember, the key to success lies in selecting the right bit for the job, considering factors such as workpiece material, project requirements, bit size, and surface finish expectations. By following the tips and best practices outlined in this article, you’ll not only achieve professional-quality results but also ensure a safer and more enjoyable woodworking experience.

So, whether you’re a seasoned pro or just starting your woodworking journey, mastering the art of bit selection will open up a world of possibilities, allowing you to bring your creative visions to life with precision and ease.

Focus Keyword: router bits

SEO Title: Straight Router Bits vs. Spiral Bits: A Woodworker’s Guide

Meta Description: