In the realm of woodworking and crafting, precision and finesse often go hand in hand. Among the tools that embody this principle is coping saws, an indispensable companion for intricate cuts, delicate designs, and intricate projects. From the hands of skilled artisans to the workshops of hobbyists, the coping saw carves a niche for itself as a versatile and indispensable tool. Join us as we delve into the world of coping saws, exploring their anatomy, essential skills, wide-ranging applications, and the art of choosing and caring for these remarkable tools.

Key Takeaways

| Key Takeaway | Description |

|---|---|

| Versatility Across Disciplines | Coping saws excel in intricate woodworking, delicate metalworking, and precise plastic cutting. |

| Mastering Essential Techniques | Proper blade selection, tensioning, and cutting techniques ensure precise and efficient results. |

| Types for Specific Needs | Different types of coping saws cater to specific requirements, from fretwork to heavy-duty construction. |

| Maintenance and Care | Proper maintenance, cleaning, and storage practices extend the lifespan and performance of coping saws. |

| Safety Precautions | Protective gear and proper work practices are paramount for safe coping saw usage. |

| Anatomy of a Coping Saw | The coping saw comprises a frame, blade, and tensioning mechanism, each with specific functions. |

| Intricate Woodworking | Coping saws excel in fretwork, scrollwork, and dovetail joints, creating intricate designs and patterns. |

| Delicate Metalworking | They enable precise cutting of thin sheets, pipes, and intricate metal shapes. |

| Precise Plastic Cutting | Coping saws are adept at cutting plastic materials like acrylic, PVC, and polycarbonate. |

| Types of Coping Saws | U-Frame, Pin-End, and Adjustable coping saws cater to different needs and applications. |

| Blade Quality | High-quality blades with sharp teeth and durable construction ensure optimal cutting performance. |

| Handle Ergonomics | A comfortable and well-designed handle reduces fatigue during extended use. |

| Cleaning and Lubrication | Regular cleaning and lubrication maintain the saw’s performance and prevent rust. |

| Blade Replacement | Replace dull or damaged blades promptly to maintain cutting efficiency. |

| Proper Storage | Store the saw in a dry, secure location away from moisture and extreme temperatures. |

The Anatomy of a Coping Saw

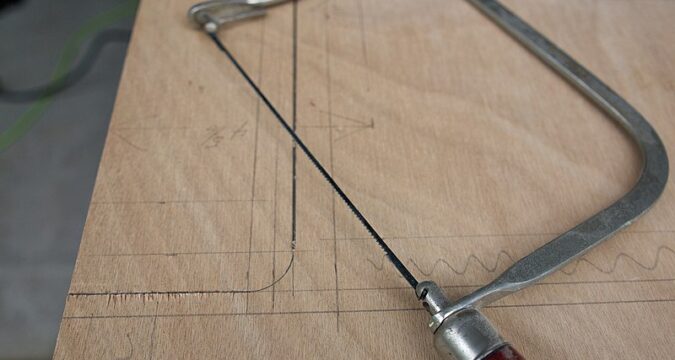

A coping saw is an intricate tool composed of several key components, each playing a crucial role in its functionality.

Frame: The foundation of the coping saw, the frame determines its overall size and shape. Typically made from metal or plastic, the frame provides stability and support during cutting operations.

Blade: The heart of the coping saw, the blade, is responsible for executing precise cuts. Blades come in various sizes, shapes, and tooth configurations, catering to different materials and cutting applications.

Tensioning Mechanism: This mechanism, often a thumbscrew or lever, allows for adjusting the blade tension. Proper tension is essential for maintaining blade stability and preventing deflection during cutting.

Essential Skills for Coping Saw Mastery

Harnessing the full potential of a coping saw requires mastering fundamental techniques and safety practices.

1. Selecting the Appropriate Blade

The choice of blade is crucial for achieving optimal cutting results. Consider the material being cut, the desired cut quality, and the saw’s frame size when selecting a blade.

2. Maintaining Proper Tension

Adequate blade tension is paramount for precise and controlled cuts. Follow the manufacturer’s instructions for adjusting the tensioning mechanism to achieve the desired blade натяжение.

3. Executing Precise Cuts

Hold the coping saw firmly with one hand and guide the blade with the other. Apply gentle pressure and maintain a steady cutting motion to achieve clean and accurate cuts.

4. Observing Safety Precautions

Always wear protective gear, including safety glasses, gloves, and a dust mask, when using a coping saw. Secure the workpiece firmly to prevent movement and maintain control.

Wide-Ranging Applications of Coping Saws

Coping saws shine in a diverse range of projects, demonstrating their versatility and adaptability.

1. Intricate Woodworking

Coping saws are ideal for intricate woodworking projects, such as fretwork, scrollwork, and dovetail joints. Their ability to make tight curves and intricate patterns makes them indispensable for detailed designs.

2. Delicate Metalworking

Coping saws also excel in delicate metalworking applications, such as cutting thin sheets, pipes, and intricate shapes. Their precision and control make them suitable for intricate metalworking projects.

3. Precise Plastic Cutting

Coping saws are adept at cutting plastic materials, including acrylic, PVC, and polycarbonate. Their fine blades and controlled cutting action produce clean and precise cuts in plastic sheets and shapes.

Choosing the Ideal Coping Saw

Selecting the right coping saw depends on your specific needs and skill level. Consider the following factors when making a choice:

1. Coping Saw Types

U-Frame Coping Saws: These saws feature a U-shaped frame, providing stability and control for general-purpose cutting applications.

Pin-End Coping Saws: These saws have a pin at the end of the frame, allowing for blade changes without removing the frame from the workpiece.

Adjustable Coping Saws: These saws feature an adjustable frame, enabling you to cut at various angles and depths.

2. Blade Quality

The quality of the blade is a key determinant of the coping saw’s performance. Look for blades made from high-quality steel, with sharp teeth and a durable construction.

3. Handle Ergonomics

Consider the saw’s handle design and ergonomics. A comfortable and well-designed handle reduces fatigue during extended use.

Caring for Your Coping Saw

Proper maintenance ensures optimal performance and extends the lifespan of your coping saw.

1. Cleaning and Lubrication

Regularly clean the saw’s frame and blade to remove sawdust and debris. Apply a light coat of oil to the blade to prevent rust and maintain smooth operation.

2. Blade Replacement

Replace dull or damaged blades promptly to maintain cutting efficiency. Follow the manufacturer’s instructions for safe blade removal and installation.

3. Proper Storage

Store the coping saw in a dry and secure location, away from moisture and extreme temperatures. Keep the blades protected to prevent damage.

Conclusion

Coping saws are versatile and indispensable tools for intricate cutting tasks in woodworking, metalworking, and plastic cutting. By mastering essential techniques, choosing the right saw, and practicing proper maintenance, you can unlock the full potential of coping saws and create stunning and precise projects.

Embark on a journey of creativity and precision with your coping saw, transforming your ideas into tangible works of art. Share your coping saw projects and experiences in the comments section below, and let’s inspire each other with our woodworking adventures.

FAQs

1. What safety precautions should I take when using a coping saw?

- Wear protective gear, including safety glasses, gloves, and a dust mask.

- Secure the workpiece firmly to prevent movement and maintain control.

- Avoid cutting near electrical wires or flammable materials.

2. How do I choose the right coping saw blade?

- Consider the material being cut, the desired cut quality, and the saw’s frame size.

- Choose blades made from high-quality steel, with sharp teeth and a durable construction.

- Select the appropriate tooth count for the desired cut finish.

3. How do I maintain proper blade tension?

- Follow the manufacturer’s instructions for adjusting the tensioning mechanism.

- Ensure the blade is taut but not excessively tight to prevent breakage.

- Check the blade tension regularly and adjust as needed.

4. What are some common applications for coping saws?

- Intricate woodworking, such as fretwork, scrollwork, and dovetail joints.

- Delicate metalworking, such as cutting thin sheets, pipes, and intricate shapes.

- Precise plastic cutting, including acrylic, PVC, and polycarbonate sheets and shapes.

5. How do I care for my coping saw?

- Clean the saw’s frame and blade regularly to remove sawdust and debris.

- Apply a light coat of oil to the blade to prevent rust and maintain smooth operation.

- Replace dull or damaged blades promptly.

- Store the coping saw in a dry and secure location, away from moisture and extreme temperatures.

6. What are some additional tips for using a coping saw effectively?

- Use a sawing motion with gentle pressure to avoid blade deflection.

- Support the workpiece properly to prevent movement and ensure clean cuts.

- Use a sawing guide or straight edge for precise straight cuts.

- Practice on scrap material to gain confidence and develop your skills.

7. Where can I find additional information and inspiration for coping saw projects?

Coping Saw Basics – This article from Fine Woodworking provides a comprehensive overview of coping saws, including their anatomy, essential skills, and various applications.

YouTube Video: Coping Saw Basics – How to Use a Coping Saw – This video tutorial from Matthias Wandel demonstrates the fundamental techniques of using a coping saw, including blade selection, tensioning, and cutting techniques.

How to Choose and Use a Coping Saw – This video offers practical advice on selecting the right coping saw for your needs, as well as tips for maintaining and using the tool effectively.