Woodworking remains a popular hobby in 2023, with more people looking to not just build items for themselves but also discover woodworking projects that sell for added income. The right DIY wood projects can easily be converted into successful side businesses or full-time creative outlets.

This article will provide tips on five proven woodworking projects that sell well in 2023 based on market demand, ease of build, and profit potential. We’ll also showcase key statistics, provide safety guidelines, and answer common questions about monetizing wood craftsmanship.

Key Takeaways

- Bathtub caddies are a top-selling functional wood accent that can retail for $80-$250

- Small wooden toys like planes or trains allow makers to tap into the $27B/year toy industry

- Custom furniture pieces like benches, shelves, and tables are always in demand for household, office, and outdoor settings

Bathtub Caddy | Egg Rack | Toy Airplane | Key Holder | Wooden Bench

Bathtub Caddy

The bathtub caddy remains one of the most profitable woodworking projects an artisan can create. Waterproof wooden bathtub caddies sell for $80 to $250 depending on size, design, and included features. They are a popular accent piece for master bathroom renovations or gift for self-care enthusiasts.

This project only requires a few key materials:

- Hardwood planks, usually teak or pine

- Wood glue

- Screws and hardware

- Waterproof varnish

The basic construction is simple. Cut the wood planks to size, join together with glue and screws to form shelves and sides, sand thoroughly, and apply at least three coats of marine-grade varnish. Include built-in holders for candles, bottles, or books.

83% of homeowners upgrade their bathrooms in the first 3 years of moving in, creating strong demand for accessories like custom caddies. Target selling these on Etsy, Facebook Marketplace, or at craft fairs by networking with interior designers, home stagers, or real estate agents who can connect you to new homeowners.

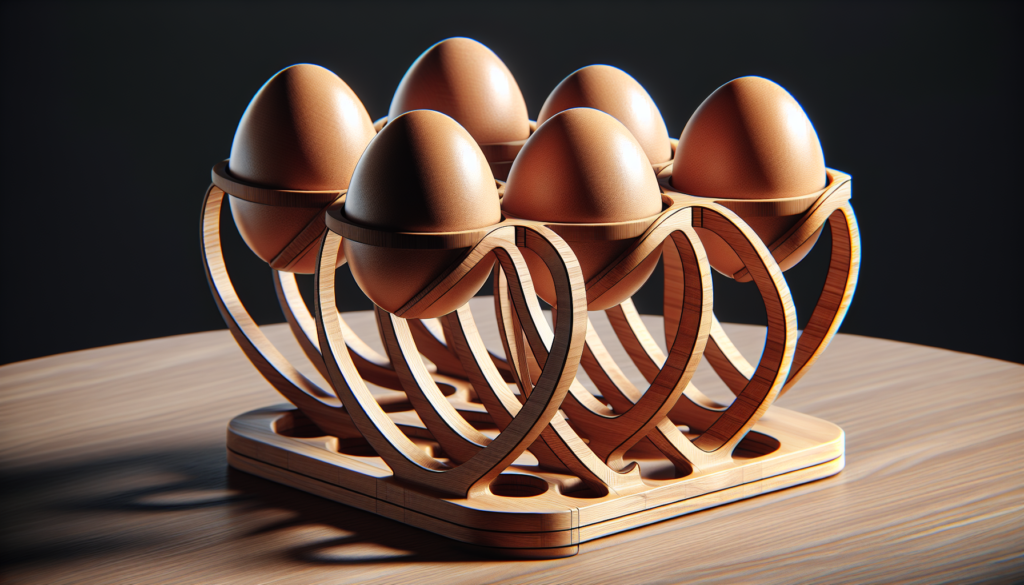

Wooden Egg Rack

Wooden egg racks remain popular among homesteaders and those raising backyard chickens. They make fantastic quick woodworking projects using minimal materials. Plus, egg racks usually retail for $30 to $60, allowing decent profit from a simple build requiring:

- Softwood planks or plywood

- Paint, stain, or varnish

- Wood filler

- Finish nails

Cut wood planks into strips, embellish fronts with decorative wood burning or carving, then join strips together with wood filler, glue, and nails to hold 2 dozen eggs securely. Add a hanger and finish with paint or stain.

Over 17 million households now keep backyard chickens, causing demand for functional items like egg storage racks to continue rising annually. These wood pieces sell particularly well at farmers markets, through local chicken enthusiast groups, or in online shops.

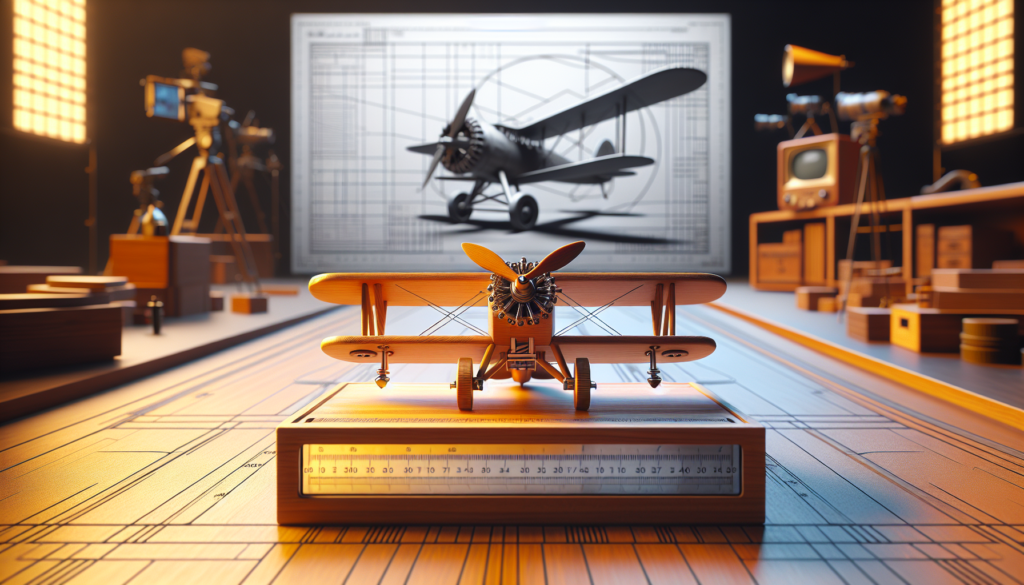

Wooden Toy Airplane

Parents today increasingly look for ethically-sourced, non-toxic children’s toys made from sustainable materials. That makes toy planes, trains, and cars craved woodworking projects for makers hoping to tap into the nearly $27 billion annual toy industry.

The materials needed for a basic wooden toy airplane are relatively affordable and easy to source:

- Plywood or balsa wood

- Wood dowels for axles/engines

- Wooden wheels

- Acrylic paints

Construct the main body from plywood pieces glued together and shape with saws and sandpaper. Paint details like windows, then attach wooden wheels and dowel axles. These imagination-sparking toys sell particularly well through online marketplaces, at craft shows where parents shop, or to specialty toy, gift, or children’s book stores seeking unique inventory like artisan wooden playthings.

Wooden Key Holder

This popular woodworking project helps keep entryways organized in style. Wooden key holders outfitted with hooks offer convenient landing zones for households or businesses constantly juggling keys, badges, lanyards, and more. Selling for approximately $25 to $60 each, this basic build can become quite profitable. DIY artisans mainly require:

- Wood plank, slice of log, or reclaimed board

- Screw hooks

- Stain, paint, or varnish

Cut wood to desired shape, drill pilot holes, and screw cup hooks along the grain. Consider burning initials or embellishing with other personalization techniques before applying protective finish.

Over 92 million households contain at least one member constantly misplacing keys. With the global key holder resale market expected to top $330 million by 2027, now is an ideal time for woodworkers to tap into this demand. Target selling these organizational pieces through furniture shops and boutiques, home and office organizers, corporate gifts vendors, and online marketplaces.

Wooden Bench

Wood benches never go out of style for indoor and outdoor spaces. As versatile seating, decor accent, or display foundation in home and commercial settings, this woodworking project offers makers seemingly infinite design options while working with widely available materials:

- Lumbers like cedar, redwood, pine

- Screws, bolts, drill bits

- Stains, paints, sealants

Construct the bench base from sturdy woods joined together with woodworking joints, glue, and steel hardware for added support. Style the seat with slatted or solid panels and embellish sides or backrests as desired before protecting the wood from weathering.

Over 65% of households invest in new porch, patio, or backyard furniture every 4 years to keep up with trends. Additionally, parks, trails, hospitality businesses, events centers, and other public spaces provide nearly endless opportunities for makers to sell artisan benches.

Woodworking Safety

Before selling any handcrafted wood pieces, every maker should learn critical woodworking safety rules. Be sure to:

- Wear goggles, respirators, hearing protection, and other PPE

- Keep fingers away from spinning blades

- Unplug tools before changing bits or blades

- Follow all manufacturer safety guidelines for power tools

- Never work while tired or distracted

- Ask for assistance when handling large lumbers

Additionally, modest insurance policies protect yourself and any employees from potential customer claims of injury from your products.

Frequently Asked Questions

Below are answers to some common questions about incorporating woodworking projects into educational settings safely:

Is wood dust in workshops dangerous?

Yes, wood dust can be harmful if inhaled regularly. Dust from cut lumber, sanding, or tooling contains chemicals linked to nasal, respiratory, and lung problems. Always ventilate workspace dust properly and wear N95 respiratory masks.

What safety equipment should students use?

Students should wear ANSI-rated eye protection, hearing protection, dust masks, and closed toe shoes when woodworking. Require collared shirts, tie back long hair, remove loose jewelry, and enforce strict usage guidelines for sharp tools.

Should machine guards always stay on woodworking power tools?

Absolutely, guards protect users from blades, bits, and flying debris. Ensure guards are kept in working order and remind students to never bypass or disable safety mechanisms.

How can I childproof my makerspace from unsafe woodworking habits?

Store all sharp tools, smaller pieces, and hazardous materials locked away when not supervised. Mount emergency shut off switches low for easy access. Post safety guidelines visibly by each workstation and hold mandatory training before access.

What first aid supplies should every woodshop have?

Outfit woodshops with fully stocked first aid kits, trauma kits for severe lacerations, accessible fire extinguishers, and eye wash stations. Ensure multiple staff are trained in injury response protocols like bleeding control and CPR.

Is there an international safety standard for woodworking programs?

Yes, schools can align their safety management plans with ISO 19085-1. This comprises risk assessments, control measures, training, machine protocols, PPE, and health monitoring guidelines.

How can I make sure power tools meet safety expectations?

Inspect cords, guards, switches buttons, blades, belts, locks, and all other parts before deploying any tool. “Lister for unusual vibrations, smells, or sounds during subsequent use. Always unplug completely before adjustments.

Regardless of which woodworking projects you pursue selling, prioritizing safety helps ensure both profitability and ability to avoid liability risks. Monitor best practices, continuously train yourself and any staff, and invest appropriately in personal protective equipment for your workshop.

Start Crafting for Profit

As you explore new woodworking projects to potentially build a business around in 2023, remember to focus on both profitability and safety. Analyze local consumer demand to pick products aligned with your regional target demographics and home design trends while also factoring in material behaviors and comfort with various tools or technical builds. Always pursue comprehensive safety certifications and insurance to protect both yourself and clients in the event of disputes.

For more guidance on cost-effectively launching and scaling a custom wood crafting side business, check out the following: